|

|

|

|

|

|

|

| |

|

| "U4X39SES"鋼索之特點 |

| 一、優異的不旋轉性 |

|

| |

使用中,鋼索不會互相纏繞,單繩起吊亦不會旋轉。 |

|

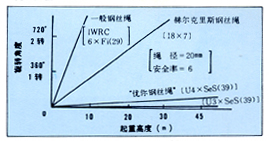

各種鋼索的起動高度與旋轉角度之比較 |

|

| |

|

| 二、極少變形 |

五、柔軟性特佳 |

| |

結構簡單,不會變形 |

|

繩股蕊心使用特殊纖維柔軟性強,使用簡便。 |

| |

|

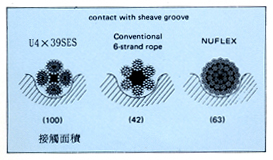

| 三、耐磨性特強 |

六、耐疲勞性優異 |

| |

由於經過特殊加工,表面平滑、耐磨性強,與繩輪或捲筒均能很好地配合。 |

|

因係線接觸鋼索,耐疲勞姓優異。 |

|

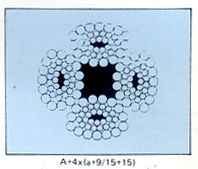

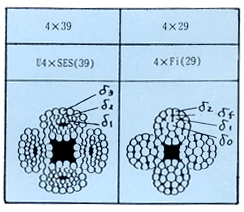

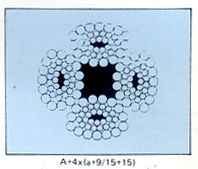

U4X39與4X29結構比較

|

| 四、破斷載荷大 |

|

| |

"優你鋼索"內含纖維蕊的SES39的繩股進行特殊加工製成,因此有效斷面積大,破斷載荷亦隨之提高。 |

|

| |

|

|

| |

| 神鋼鋼索 U4X39SES |

| 用途 |

| ●特別高度、重量之起重機用鋼索 |

| ●施工機械之起重鋼索 |

| ●鑿井之起重鋼索 |

| ●打椿機械用鋼索 |

| ●輸電線施工用鋼索 |

| ●其他需要使用不旋轉鋼索之作用 |

| |

| 使用及適用實例 |

| ●施工機械:汽車起重機 |

| |

履帶式起重機 |

| |

塔式液壓式起重機 (光面鋼索10~25mm) |

| |

機械式起重機(光面鋼索16~37.5mm) |

| |

廠牌P&H (KOBE) |

| |

KATO |

| |

TADAN0 |

| |

HITACHI等 |

| |

| ●船用起重機:甲板起重機 (鍍鋅鋼索20mm~45mm) |

| ●輸電線施工用延線鋼索 (鍍鋅鋼索8mm~25mm) |

| |

| 使用上應注意要點 |

| 在使用上,與一般鋼索相同,但為使它發揮不旋轉性及其特殊效果,請特別注意下列兩點: |

| (1)"U4X39SES"因係一種回跳式捻繩,切斷時,必須用軟鋼絲將切斷位置的兩端梱緊堅固後,再進行切斷。 |

| (2)由於某種原因,鋼索捻得過緊或倒捻鬆股時,應將鋼索放下來修正後再使用。 |

|

|

| STEEL WIRE ROPE Type SEL-054 UNIROPE |

Steel Wire Rope rotation-resistant, and resistant to wear. Recommended for use as hoist rope on derrick cranes, tower cranes, and all kinds of deck cranes with high lift on single-part., as well as double,or multiple-part operation. Suitable for use as winch line for all kinds of crane, excavator and drilling operations, as well as similar applications. |

|

| Construction: |

4 x 39 (F+9+15+15)FC |

| Type of Lay: |

Cross Lay (Regular, Ordinary) |

| Direction of Lay: |

Right Hand, or Left Hand |

Tensile Grades(nominal

tensile strengths): |

SEL-054-S =1620N/mm2(165 kgf/mm2)

SEL-054-H =1770N/mm2(180 kgf/mm2)

SEL-054-SH=1920N/mm2(195 kgf/mm2) |

| Finish: |

bright, or galvanized. |

| Characteristics: |

| ● |

Rotation-resistant (see diagram Fig. 2 page 4), rotation resistance achieved by method of |

| |

production (dasically special forming process after closing operation). |

| ● |

Resistant to outside mechanical damage, like chafing, cutting, crushing, or jolting effects, |

| |

owing to solid rope-structure (avoids dird-cages, broken wires, or strands). |

| ● |

Optimum load-elongation ratio (see diagram Fig. 1 page 4) |

| ● |

Little fatigue in bending, and little inside wear, owing to parallel lay of wires inside the |

| |

strands. |

| ● |

Optimum surface contact between rope and grooves of sheaves, and drums, thus optimum |

| |

distribution of radial pressure (resulting from flattened shape of strands, and surface wires). |

| ● |

Highly flexible owing to fibre cores in the strands;rallowing easy installation. |

| |

|

| Important: |

| ● |

Forming process after closing operation reduces preforming effect, therefore rope-ends to be |

| |

seized. |

| ● |

Ropes re-wound from production reels to shipping reels;reduces remains of spin left over |

| |

from winding on production reel.(Allows winding of rope from shipping reel directly to drum). |

| ● |

Test Certificate available from any classification bureau. |

| |

|

|

Nominal-Rope-Diameter

直徑mm

-0+7%

Tol |

Metallic

Area

mm2 |

Outer

Wire

Dia.

mm |

Weight

重量

kg/m |

Minimum Breaking Strength 拉斷強度

when tensile Grade |

1620 N/222(165kgf/mm2)

Grade S |

1770 N/222(180kgf/mm2)

Grade H |

1920 N/222(195kgf/mm2)

Grade SH |

| kN |

kgf |

kN |

kgf |

kN |

kgf |

| 8 |

28.7 |

0.56 |

0.261 |

37.6 |

3830 |

41.0 |

4180 |

44.4 |

4530 |

| 9 |

36.4 |

0.63 |

0.330 |

47.4 |

4830 |

51.9 |

5280 |

56.1 |

5720 |

| 10 |

44.9 |

0.71 |

0.408 |

58.6 |

5980 |

63.9 |

6520 |

69.2 |

7060 |

| 11.2 |

56.3 |

0.80 |

0.512 |

73.6 |

7500 |

80.3 |

8190 |

87.0 |

8870 |

| 12 |

64.7 |

0.85 |

0.588 |

81.6 |

8320 |

89.0 |

9080 |

96.5 |

9840 |

| 12.5 |

70.2 |

0.90 |

0.638 |

91.7 |

9350 |

100 |

10200 |

109 |

11100 |

| 14 |

88.0 |

1.00 |

0.800 |

115 |

11700 |

126 |

12800 |

136 |

13900 |

| 16 |

115 |

1.12 |

1.04 |

150 |

15300 |

164 |

16700 |

178 |

18100 |

| 18 |

145 |

1.25 |

1.32 |

190 |

19400 |

208 |

21200 |

226 |

23000 |

| 19 |

162 |

1.32 |

1.47 |

212 |

21600 |

231 |

23600 |

251 |

25600 |

| 20 |

180 |

1.40 |

1.63 |

234 |

23900 |

256 |

26100 |

278 |

28300 |

| 22 |

217 |

1.57 |

1.97 |

283 |

28900 |

310 |

31600 |

335 |

34200 |

| 22.4 |

225 |

1.60 |

2.05 |

294 |

30000 |

322 |

32800 |

3489 |

35500 |

| 24 |

259 |

1.70 |

2.35 |

326 |

33200 |

356 |

36300 |

385 |

39300 |

| 25 |

281 |

1.80 |

2.55 |

366 |

37300 |

399 |

40700 |

432 |

44100 |

| 26 |

303 |

1.85 |

2.76 |

395 |

40300 |

431 |

44000 |

467 |

47600 |

| 28 |

352 |

2.00 |

3.20 |

460 |

46900 |

502 |

51200 |

543 |

55400 |

| 30 |

405 |

2.12 |

3.73 |

528 |

53800 |

576 |

58700 |

624 |

63600 |

| 31.5 |

445 |

2.24 |

4.10 |

582 |

59300 |

634 |

64700 |

687 |

70100 |

| 32 |

460 |

2.27 |

4.23 |

600 |

61200 |

655 |

66800 |

709 |

72300 |

| 33.5 |

506 |

2.36 |

4.64 |

658 |

67100 |

718 |

73200 |

778 |

79300 |

| 34 |

519 |

2.40 |

4.78 |

678 |

69100 |

739 |

75400 |

801 |

81700 |

| 35.5 |

568 |

2.50 |

5.21 |

739 |

75400 |

806 |

82200 |

873 |

89000 |

| 36 |

582 |

2.55 |

5.36 |

760 |

77500 |

829 |

84500 |

897 |

91500 |

| 37.5 |

634 |

2.65 |

5.81 |

825 |

84100 |

899 |

91700 |

974 |

99300 |

| 38 |

648 |

2.70 |

5.97 |

847 |

86400 |

924 |

94200 |

1000 |

102000 |

| 40 |

718 |

2.80 |

6.61 |

920 |

93800 |

1000 |

102000 |

1079 |

110000 |

| 42 |

792 |

2.95 |

7.29 |

1010 |

103000 |

1108 |

113000 |

1196 |

122000 |

| 42.5 |

811 |

3.0 |

7.46 |

1040 |

106000 |

1128 |

115000 |

1226 |

125000 |

| 44 |

869 |

3.1 |

8.02 |

1108 |

113000 |

1216 |

124000 |

1314 |

134000 |

| 45 |

909 |

3.15 |

8.37 |

1167 |

119000 |

1265 |

129000 |

1373 |

140000 |

|

|

|

|

|

|

|

|

|